The Massive Future of 3D Printing

Massive 3D Printing; Introducing Bigger & Faster Prints

World's Largest 3D Printed Boat

3D printing is getting bigger and faster. Over the years, we have seen a notable increase in massive 3D printing.

In fact, a group of researchers from the University of Maine recently revealed the world’s largest 3D printed boat. Named 3Dirigo, the boat was 3D printed in merely 72 hours. It was built using the largest prototype polymer 3D printer developed by the UMaine Advanced Structures and Composites Center.

3Dirigo was printed using a mixture of plastic and wood cellulose. It boasts a length of 7.62 meters and weighs almost 2000 kilograms.

Massive 3D Printing For Construction

1. Largest 3D Printed Building

Other than 3D printing the world’s largest boat, 3D printing has been used for buildings too. The world’s largest 3D printed building to date is a two-storey building situated in Dubai. This building is 9.5m tall and boasts a total area of 6,889 square feet.

The structure was built by layering a fluid material along a predetermined route mapped out by computer, similar to an inkjet printer. The mineral-infused fluids solidify into concrete almost instantly, hence forming the three-dimensional building. Impressively, this huge structure was only built with 15 people!

2. First 3D Printed Bathroom

3D printing has also been incorporated in parts of construction. Earlier this year, researchers from Nanyang Technological University (NTU) unveiled the world’s first 3D printed unfurnished bathrooms. The 1.6m by 1.5m by 2.8m bathroom was 3D printed in 9 hours. Usually, prefabricated bathrooms take twice the amount of time and cost to build using concrete casting.

3D Printed Bridge Using ASA Material

A 3D printed bridge can be found in a downtown park located in Shanghai. It was 3D printed in ASA (Acrylonitrile styrene acrylate), a UV resistant material suitable for outdoor commercial and infrastructure use. The bridge weighs about 5000kg, and is 15.25 metres long, 3 metres wide, and 1.2 metres high.

Massive 3D Printing For Rockets

Adding on to the list of massive things to 3D print, Aerospace startup Relativity Space is attempting to 3D print its first rocket. Named the Terran 1, the rocket can be built in less than 60 days by Relativity’s specialized Stargate 3D printers in Los Angeles. Stargate is the latest model of the company’s proprietary printer. It stands 30 feet tall and has two massive robotic arms. The Terran 1 rocket is designed to be about 100 feet tall and will be able to withstand 1,250 kilograms of payload. Therefore, it is theoretically capable of delivering satellites weighing up to 2,800 pounds to low Earth orbit. The only non 3D printed parts on the rocket will be electronics, cables, a few moving parts and rubber gaskets. Terran 1 is expected to fly in 2021 at the earliest after rounds of full-scale testing.

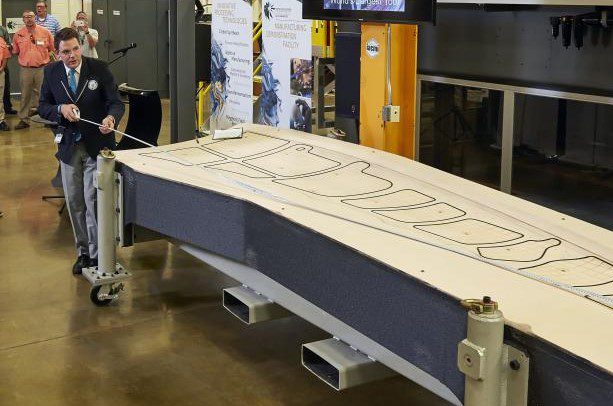

Massive 3D Printing For Aerospace Industry

The Oak Ridge National Laboratory collaborated with Boeing to produce a 3D printed aerospace tool. Measuring 17.5 x 5.5 x 1.5 ft and weighing 748kg, the part is meant to aid wing production for the Boeing 777x. It was printed in a single piece in 30 hours, using FDM 3D printing technology and ABS plastic reinforced with carbon fiber.