AM2U Solutions, also known as Additive Manufacturing to You, is a start to end 3D printing service to meet industrial needs in Singapore and the APAC. It is a personalised industrial 3D Printing & Additive Manufacturing Solution catered to your business needs.

Since the conception of Industry 4.0, 3D printing, also known as additive manufacturing, is a transformative approach to production lines and patterns. From healthcare to automotive, industrial 3D printing is a useful solution for rapid prototyping and production of end parts. Paving the way for the creation of new models and opportunities, industrial 3D printing technology and services are widely sought-after in Singapore and across the globe.

Simply a process that builds a prototype layer by layer, the additive nature of 3D printing provides designers and manufacturers the opportunity to cut down on material use and reduce components required for assembly. Given its flexibility, production cycles are contracted, and production management is simplified.

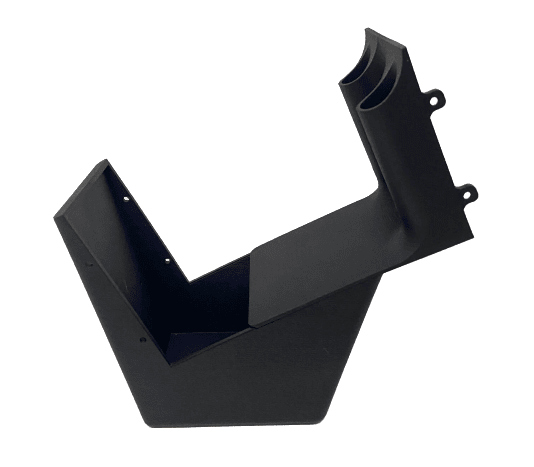

With its rapid growth and adoption, additive manufacturing can be used across a range of industries such as research, aviation, gaming, and more. As long as quality, intricate designs are required of your product prototype, our industrial 3D printing services enable us to produce realistic, true to design parts in a consistent and cost-efficient manner.

Produce functional engineering grade thermoplastic parts in full color with optimal mechanic properties, fine details and high dimensional accuracy

Short for Fused Deposition Modeling, FDM is one of the most commonly adopted additive manufacturing technologies today due to its low cost and efficiency.

Great for products that require a smooth finish and high accuracy. SLA is also a popular choice for creating prototypes for clear parts, including bottles.

SLS is a powder-based 3D printing technology suitable for building parts that require high durability and complex geometries as it does not need any form of support.

Similar to SLS, Multi Jet Fusion also utilises powder to 3D print objects. One advantage is that parts produced by MJF are stronger and more precise compared to SLS.

Using two-component polyurethanes (PU) and silicone moulds to produce high-quality prototypes and end-use products effectively.

Our 3D printing solutions are ISO 9001:2015 certified, giving us the confidence to provide you with a high-quality Additive Manufacturing experience.

Understanding and speaking the right industrial language helps us to specifically narrow down to your industry requirements and thus achieve a great result and experience.

Before project commencement, you will be able to voice your requirements and concerns. With this information, we will be able to create your ideal digital part and manufactured product within the agreed time frame.

With an easy, affordable professional service to engage, let us do the heavy lifting for you in 3D CAD Modeling and manufacturing while you focus on growing your business.