FDM 3D Printing Singapore

Upload your 3D files and get an instant quote for our online 3D printing FDM service in Singapore.

What is FDM?

Fused Deposition Modeling (FDM) is one of the most common 3D printing processes today.

The technology builds 3D printed objects by moving an extrusion nozzle over a build platform. The process involves the use of thermoplastic material that reaches the melting point. Subsequently, the filament is then extruded to create a 3D object layer by layer along a specifically determined path. These layers then fuse together to form a finished product.

Applications of Our Online 3D Printing FDM Service

FDM is widely adopted due to its low cost and fast turnaround time in comparison to other additive manufacturing technologies. The 3D printing process is clean and simple to use. Therefore, it is highly suitable for home and office use. FDM 3D printing is used across multiple industries and builds end-use products that remain unrivalled in mechanical and thermal properties. We offer online 3D printing FDM services to enhance your business workflow.

Benefits of FDM 3D Printing

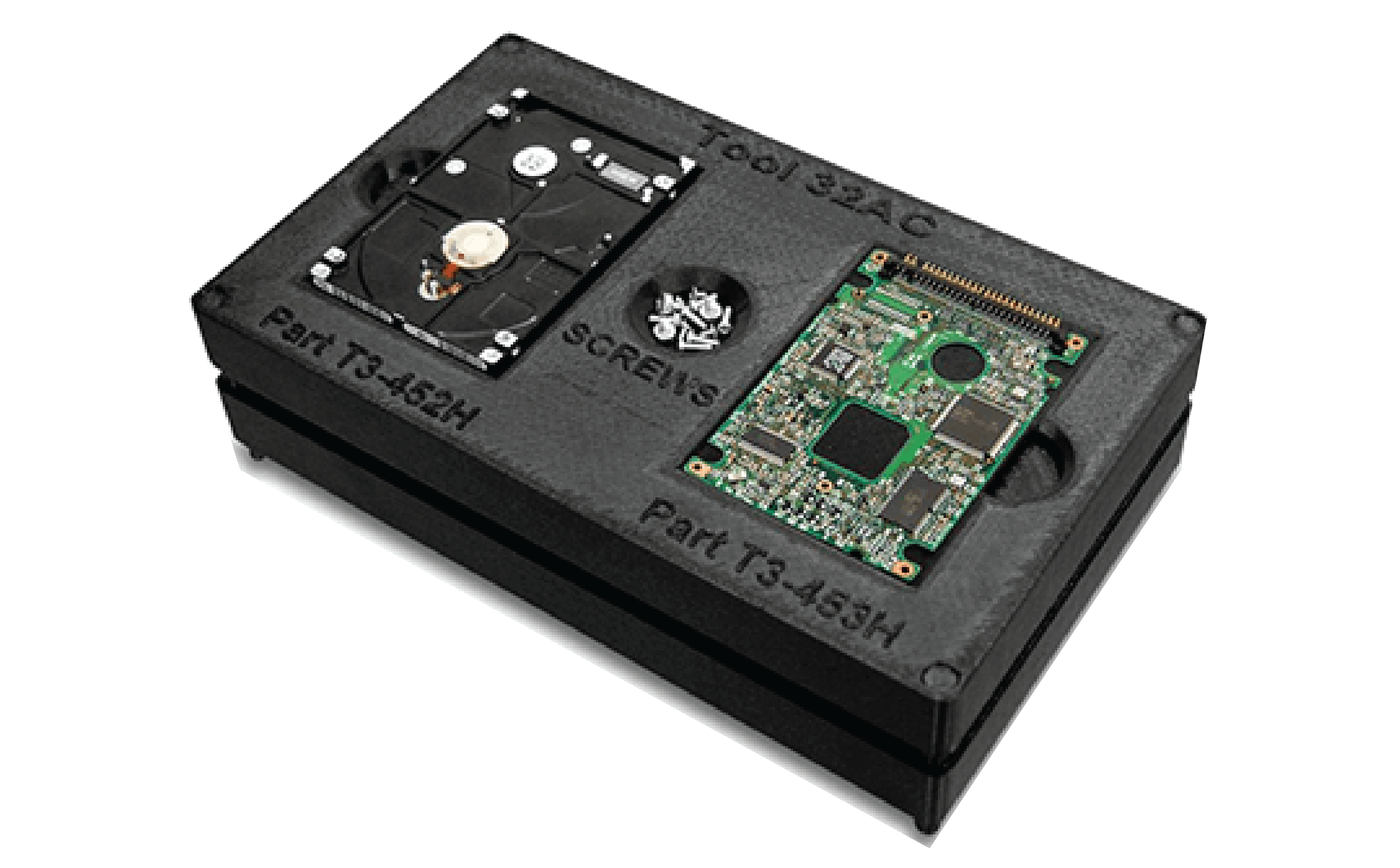

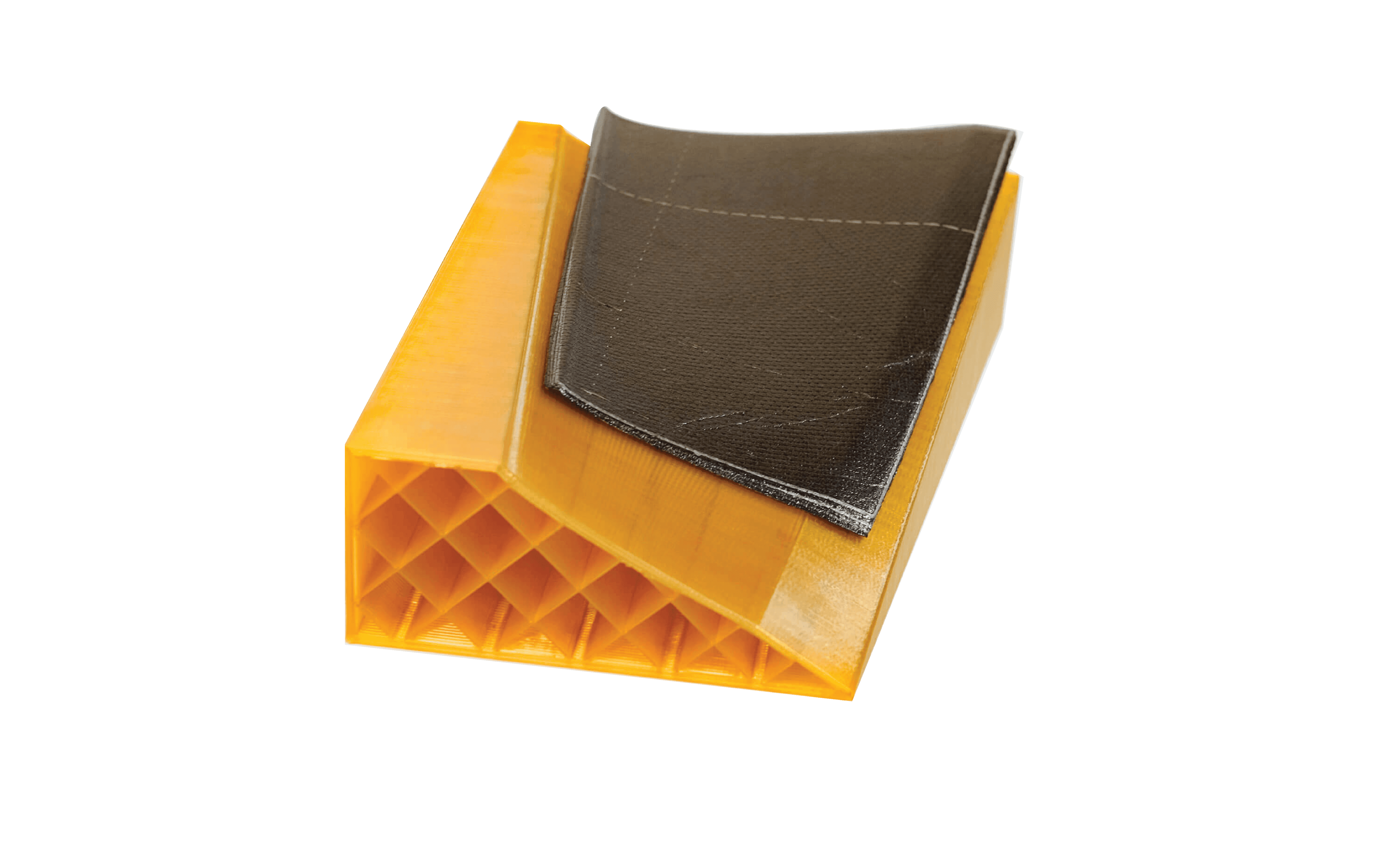

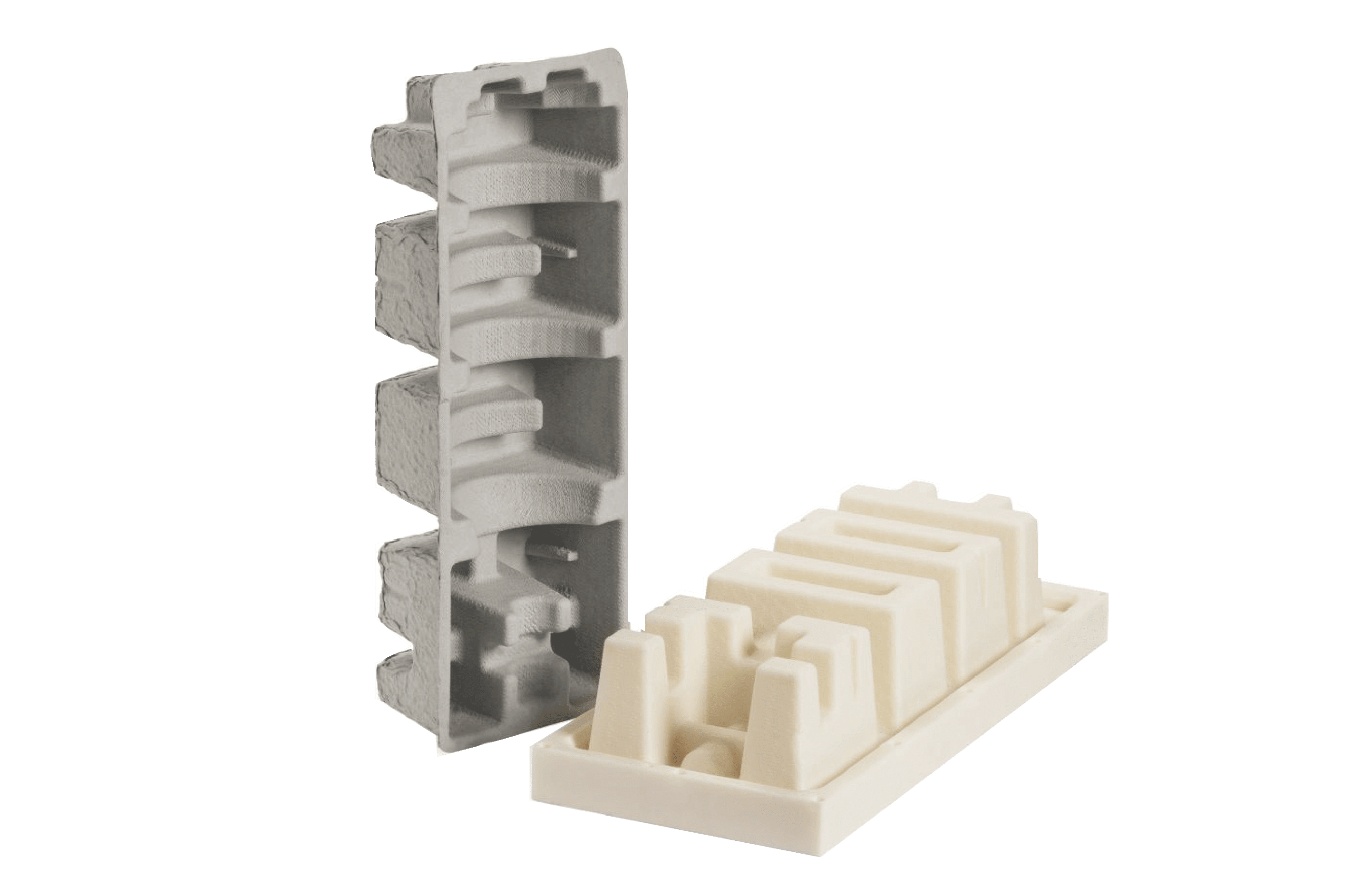

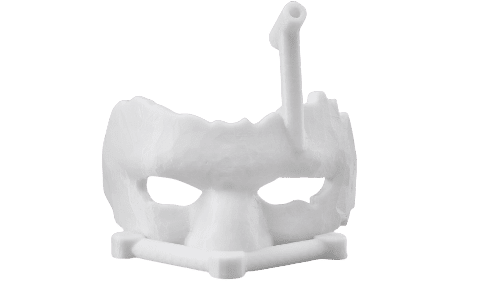

As the technology is widely accessible, it has a large range of thermoplastic filaments and materials available for selection. One of the key benefits of FDM is that its materials are highly durable. Their mechanical properties are also stable over time. Therefore, the production-grade thermoplastic materials used in FDM 3D printing are suitable for many uses. These include detailed functional prototypes, end-use parts, durable manufacturing tools as well as low-volume manufacturing parts. Beyond durability, this method of additive manufacturing is easily scalable and offers material flexibility.

Additive3D Asia is the authorised distributor for FDM 3D printers such as Cubicon Single Plus, Cubicon Style and the new Cubicon Style Plus, Cubicon Style NEO A22C and Cubicon Style NEO A31C. Standard materials available are Acrylonitrile butadiene styrene (ABS), ABS-FR (Flame Retardant), Polylactic acid (PLA), Thermoplastic Polyurethane (TPU), Polyethylene terephthalate glycol (PETG), Polycarbonates (PC) and more.

We have upgraded your in-house capacity to print from small to large size part in one piece or cater to batch production volume with our full range of industrial FDM 3D printers. Our team are also able to print and assemble parts of odd shapes, sizes and custom finishing with post processing. Get in touch with us for further discussion on your project.

FDM / FFF Materials Available:

ABS-ESD7

ABS-ESD7 prevents a build-up of static electricity for end-use components, electronic products, industrial equipment, and jigs and fixtures for assembly of electronic components.

ULTEM™ 9085 CG Resin

ULTEM™ 9085 CG resin features a high strength-to-weight ratio, high thermal and chemical resistance, and flame, smoke, and toxicity (FST) ratings. ULTEM™ 9085 CG resin possesses documented traceability from filament back to the raw material lot number.

ULTEM™ 1010 Resin

ULTEM™ 1010 resin offers superior tensile strength and excellent chemical and thermal resistance for an FDM thermoplastic. The certified grade is biocompatible and approved for food contact with NSF 51 and ISO 10993/USP Class VI certifications.

ABS

ABS is 25 to 70 percent stronger than standard ABS, making it ideal for concept modelling, functional prototyping, manufacturing tools, and end use parts. It features significantly stronger layer bonding than ABS and greater tensile, impact, and flexural strength.

ASA

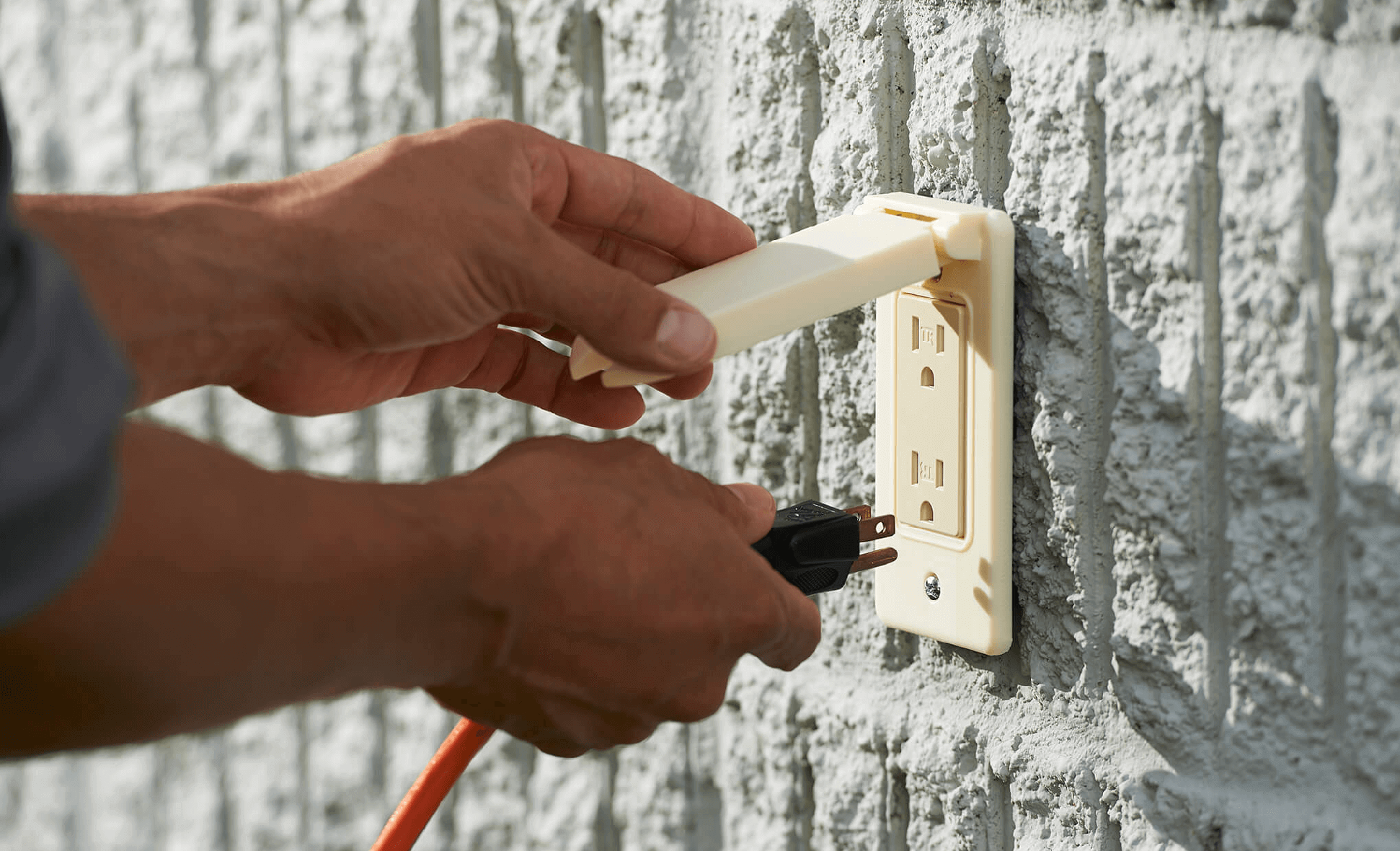

Outdoor-use production parts benefit from the strength, colour choice, and UV resistance of ASA material. From electrical housings and brackets to sporting goods and automotive prototypes, ASA’s ease of use also makes it a great choice for iterative design.

Carbon Fiber (Nylon 12CF)

3D printing with carbon fiber material lets you build strong, stiff, lightweight tools and parts. FDM Nylon 12CF combines nylon 12 and carbon fiber to achieve the highest flexural strength and the stiffness-to-weight ratio of any of our FDM materials.

PC-ISO

PC-ISO is a bio-compatible FDM thermoplastic that lets engineers create prototypes, moulds, and products in a heat-resistant material for the pharmaceutical, food packaging, and medical industries.

PC-ABS

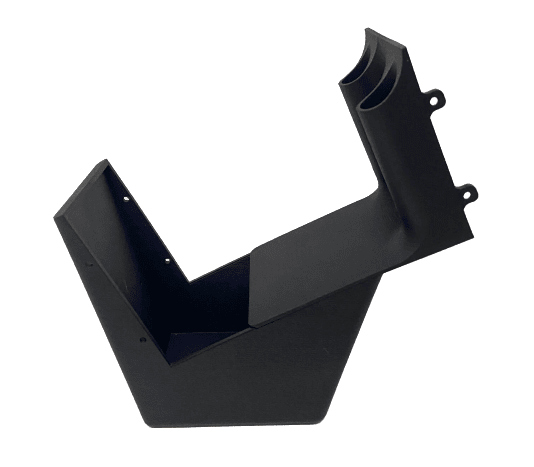

PC-ABS (polycarbonate-ABS) is one of the most widely used industrial thermoplastics. PC-ABS offers the most desirable properties of both materials – the superior strength and heat resistance of PC and the flexibility of ABS. PC-ABS blends are commonly used in

automotive, electronics and telecommunications applications. PC-ABS is 5-60 percent stronger than a part made on previous FDM systems. PC-ABS gives you conceptual modeling, functional prototyping, manufacturing tools and production parts.

Our Flame Retardant (FR) material is a premium UL94 V-0 rated ABS that allows for printing of functional prototypes and production parts.

This material is ideal for printing electrical housings, connectors, or any part that requires thermal properties [up to 95°C] and flame retardant ABS characteristics.

MarkForged Onyx

Onyx is the chopped carbon fiber reinforced nylon. It’s 1.4 times stronger and stiffer than ABS and can be reinforced with any continuous fiber. Onyx sets the bar for surface finish, chemical resistivity, and heat tolerance.

MarkForged Continues Carbon Fiber

Carbon fiber is the workhorse of the four fibers, boasting a strength-to-weight ratio 50% better than 6061 aluminum, a tensile modulus roughly equivalent to that of aluminum, and a stiffness 24 times that of ABS. If maximal strength is what you need, carbon fiber is the best option.

Please email us at [email protected] for an instant quotation today!

3D Printing Processes

FDM

Short for Fused Deposition Modeling, FDM is one of the most commonly adopted additive manufacturing technologies today due to its low cost and efficiency.

SLA

Great for products that require a smooth finish and high accuracy. SLA is also a popular choice for creating prototypes for clear parts, including bottles.

SLS

SLS is a powder-based 3D printing technology suitable for building parts that require high durability and complex geometries as it does not need any form of support.

MJF

Similar to SLS, Multi Jet Fusion also utilises powder to 3D print objects. One advantage is that parts produced by MJF are stronger and more precise compared to SLS.