Upload your 3D files and get an FREE instant quote for our SLS 3D Printing Services in Singapore, using popular materials from PA12 Nylon, PA12 Glass Filled Nylon, and Different Shore Hardness of TPU and TPE.

We offer the largest range of industrial SLS materials.

Selective Laser Sintering (SLS) is a powder-based 3D printing technology. It makes use of a high powered laser that selectively scans a thin layer of powder and sinters the small powdered plastic particles together to form 3D object, layer by layer.

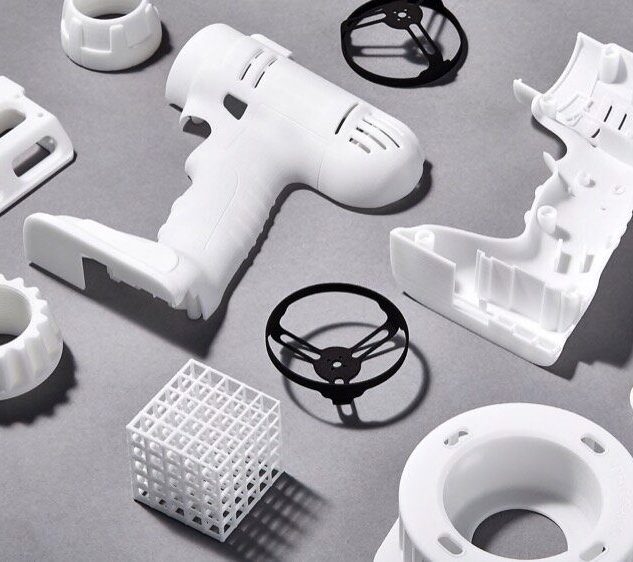

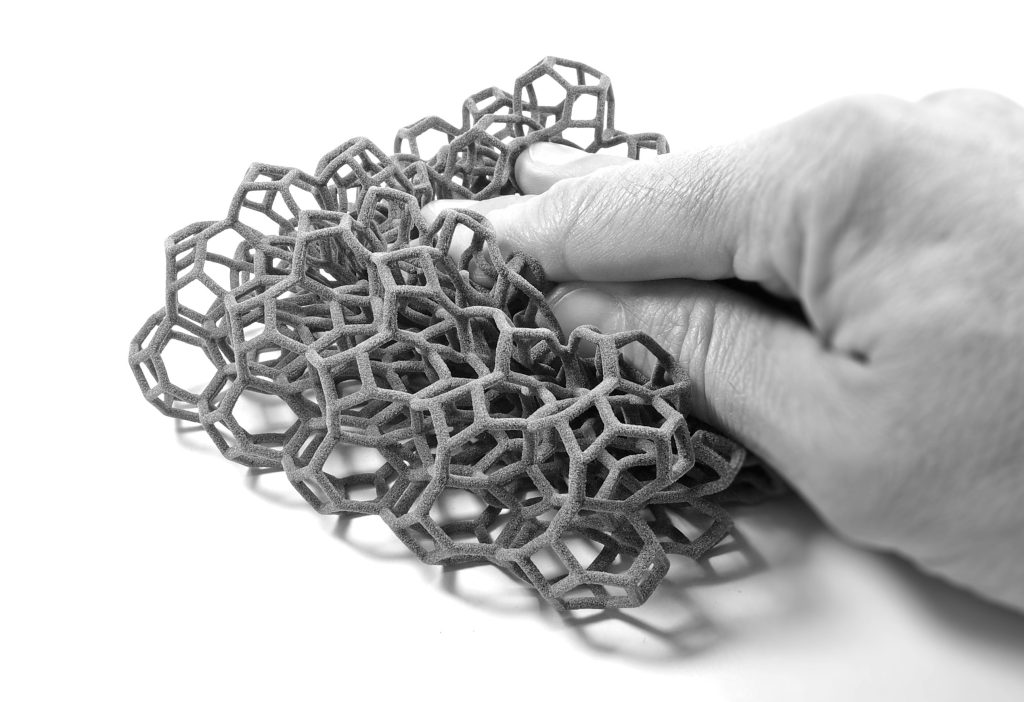

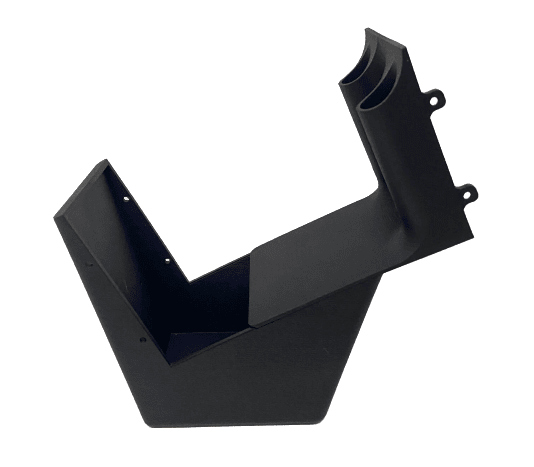

Unlike most other additive manufacturing technologies, SLS does not require any form of support as the leftover unsintered powder acts as self-supporting material. Thus, extremely complex geometries are made possible.

The technology is a great choice when 3D printing functional prototypes as SLS printed parts are robust and will not become brittle over time. In fact, the durability of parts created with SLS technology is on par with those produced through traditional manufacturing methods such as injection moulding.

In comparison to MJF, SLS also has more material options.

When it comes to 3D printing materials, the synthetic thermoplastic known popular as Nylon Polyamide (PA) is commonly used. Able to be 3D printed using SLS technology, industrial nylon SLS enables the creation of complex geometrical models that are challenging to other 3D printing technologies. Producing prototypes and functional end use parts that are strong, tough, durable and have good thermal weight loading and heat resistance capabilities.

Here are two (2) of the most common requested materials in SLS:

Glass filled nylon is a 3D printable nylon composite material. As glass filled nylon 3D printing consists of 30% glass fibers, it can be fabricated by SLS 3D printing technology to produce industrial parts with high strength and stiffness over standard nylon, simultaneously achieving low abrasive wear and complex geometries.

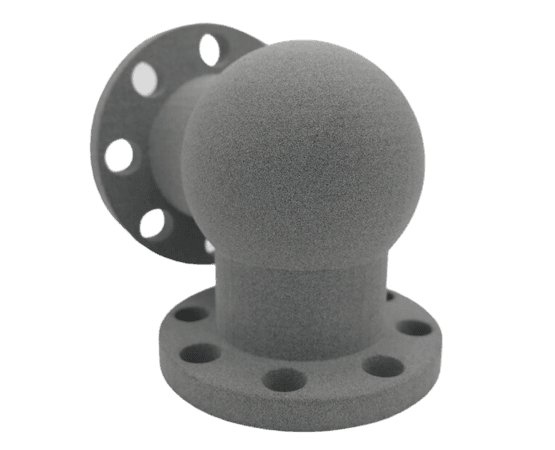

Like glass filled nylon, PA 12 is a solid polyamide material that does not require structural support. Compared to PA 11, PA 12 is a 3D printable nylon that possesses the suitable mechanical properties necessary for the creation of functional prototypes and final end use parts. There is a full range of other materials you can explore if you’re interested in PA 12 3D printing, for example PA 2200 by EOS GmbH, like PA 2201, PA 2241 FR (Fire-Retardant), and more, are variants of different polyamide (PA) 12 family.

PA 2200 meets the industry standard for high-end 3D printing due to its strength, rigidity, and chemical resistance. An affordable material, PA 2200 SLS 3D printed parts are extremely versatile and are a high-performance alternative to other less durable plastics.

Check out our other materials offering in our SLS 3D Printing Services:

White Polyamide PA 12 material for slightly more translucent parts. High strength and stiffness and various colouring and finishing options are possible.

A Grey Polyamide PA 12 powder (nylon-based compound) with good mechanical properties and excellent surface resolution.

TPU material for producing flexible parts. Similar properties to rubber, it suppresses hits and shocks well.

Glass filled Nylon (SLS) contains glass particles that give parts high stiffness and improved thermal and abrasion resistance over standard Nylon.

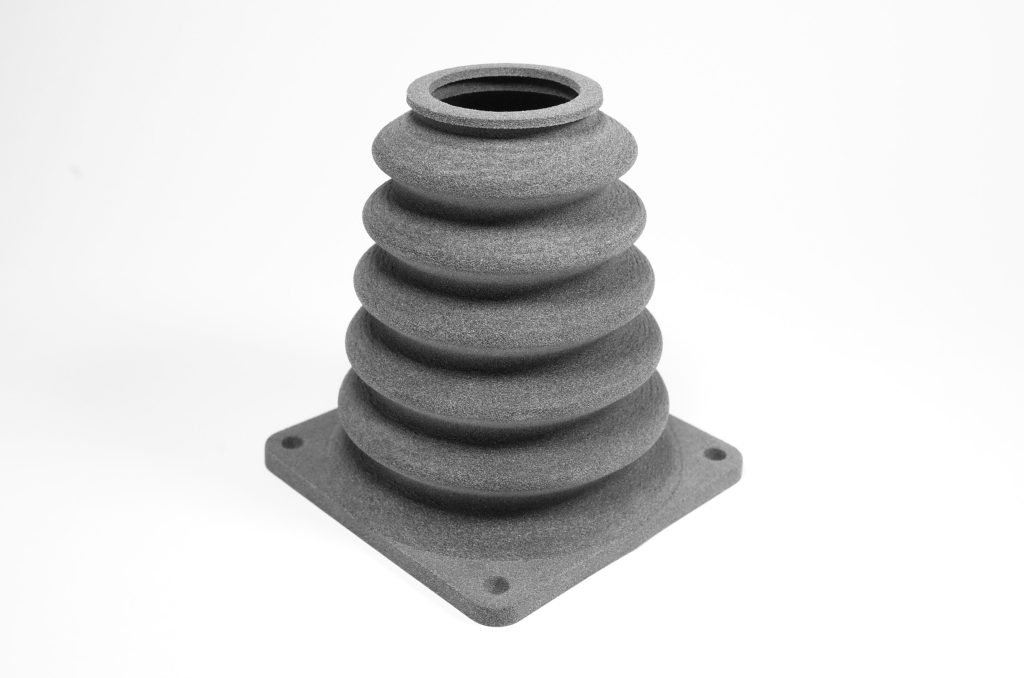

With TPE (Thermoplastic Elastomers) it is possible to print functional prototypes such as pumps, bellows, gaskets and other elastic solutions dedicated to work in difficult conditions

A TPU material that gives a possibility to create prints with really high elasticity. Flexible prints with increased extensibility. Adjustable hardness. 100% reusable.

Short for Fused Deposition Modeling, FDM is one of the most commonly adopted additive manufacturing technologies today due to its low cost and efficiency.

Great for products that require a smooth finish and high accuracy. SLA is also a popular choice for creating prototypes for clear parts, including bottles.

SLS is a powder-based 3D printing technology suitable for building parts that require high durability and complex geometries as it does not need any form of support.

Similar to SLS, Multi Jet Fusion also utilises powder to 3D print objects. One advantage is that parts produced by MJF are stronger and more precise compared to SLS.