Case Study:

Custom Made BMW Air Intake

Combining the use of 3D Modelling, 3D Printing with the law of physics.

Challenge

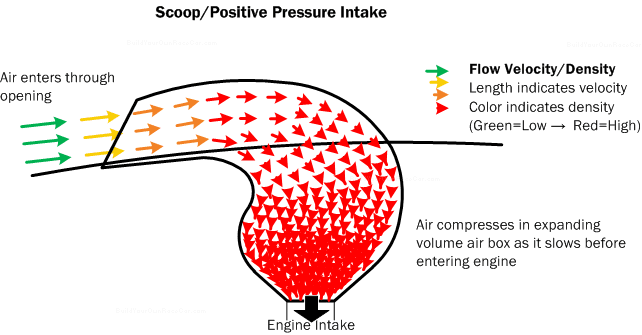

Unable to find a suitable aftermarket car part that can create a bigger plenum effect to allow bigger air reservoir in the air intake for better performance

Solution

Started with onsite inspection and 3D Modelling using references from pictures and measurements. Thereafter, a 3D model wants printed out and moulded with Carbon Fiber for the final product.

Technology

- CAD Modelling

- SLA 3D printing

- Carbon Fiber Moulding

Material

- Industrial White ABS Resin

- Carbon Fiber

Customized a one and only air-intake for Andy's BMW F10 535i

How special in this exercise is Andy wants to maximize the space that he has to make the air-intake middle section to have a much bigger plenum to allow bigger air reservoir for his car performance. Yes! Why not?

What does increasing plenum volume do?

Does a plenum effect increase power?

Final Product

In this process, we involved in CAD modeling and prototyping with our large scale industrial SLA 3D Printer from UnionTech, our final prototype give great accuracy and smooth finishing which is ideal for the next manufacturing process.

We thank him for trusting in us and we helped Andy from his idea to the final design and so he could make the final air-intake in carbon fiber.