Vacuum Casting (Urethane Casting) Services

Get production-like plastic parts fast — ideal for functional prototypes, appearance models, and short-run manufacturing without expensive hard tooling.

Best For

- Low-volume runs (typically 10–100+ parts)

- Design validation & functional testing

- Marketing samples & investor demos

- Bridge to injection molding before steel tooling

Common Industries

- Consumer products & electronics

- Automotive components

- Medical device prototypes

- Industrial equipment

What is Vacuum Casting?

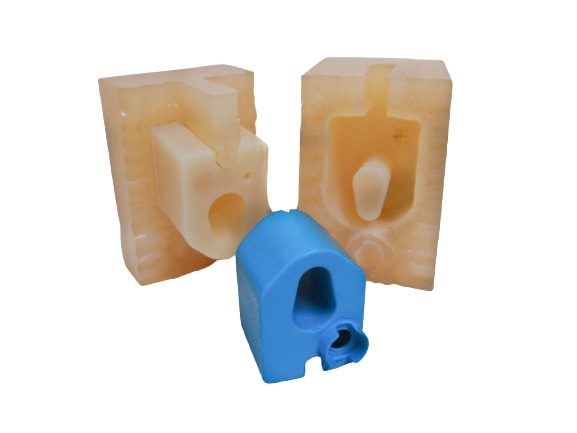

Vacuum casting (urethane casting) is a silicone moulding process that replicates parts using two-component polyurethane resins under vacuum to reduce bubbles and improve finish. It’s a practical option when you need production-like parts quickly, but don’t want to invest in metal tooling yet.

Production-Like Results

Achieve excellent cosmetic finish and realistic mechanical properties for prototypes and low-volume parts.

Flexible Iterations

Ideal when designs are still evolving—update the master and create new moulds without steel-tooling costs.

Our Vacuum Casting Process

We follow a proven workflow to deliver consistent, high-quality urethane cast parts — from master creation to finishing.

Master Pattern

Create the master using SLA 3D printing or CNC machining for accuracy, fine details and smooth surfaces.

Silicone Mould Tooling

Build a silicone mould around the master, designed for repeatable casting and easy demoulding.

Vacuum Casting

Mix and pour polyurethane resin under vacuum to minimise bubbles and capture surface detail.

Curing

Allow the resin to cure for stability and performance before demoulding and post-processing.

Finishing

Trim, sand, texture, paint, colour match, or clear coat depending on appearance and functional requirements.

QA & Delivery

Dimensional checks and visual inspection before secure packing and delivery to your team.

Why Choose Vacuum Casting?

Vacuum casting is one of the most effective ways to produce small batches that look and perform like injection-molded parts.

Lower Upfront Cost

Silicone moulds cost significantly less than metal tooling—ideal for low volumes and pilot production.

Fast Lead Times

Shorten time-to-market with rapid mould creation and efficient casting cycles.

Cosmetic Finish

Great for showcase parts, product photography and market testing with smooth, clean surfaces.

Material Versatility

Choose rigid, flexible, rubber-like, high-temp or clear resins to match intended performance.

Bridge to Production

Validate design and demand before committing to injection mould tooling investment.

Repeatable Small Batches

Produce consistent parts across short runs for pilots, trials and early-stage sales.

Vacuum Casting vs 3D Printing vs Injection Molding

Selecting the right process depends on volume, cost, lead time and the required surface finish and properties.

| Criteria | Vacuum Casting | 3D Printing | Injection Molding |

|---|---|---|---|

| Best Volume Range | 10–100+ parts | 1–50 parts | 1,000+ parts |

| Upfront Tooling Cost | Low (silicone mould) | None | High (metal tool) |

| Surface Finish | Excellent | Varies by process | Excellent |

| Material Options | High (urethane resins) | Medium | High (thermoplastics) |

| Lead Time | Short | Very short | Longer |

Typical Applications

Vacuum casting supports industries that require realistic prototypes and short-run components with great cosmetic finish.

- Consumer product prototypes & appearance models

- Electronics housings, bezels, covers & enclosures

- Automotive trims, interior components, functional parts

- Medical device concept parts and ergonomic models

- Industrial equipment covers, guards & trial assemblies

- Packaging prototypes for market testing

Materials & Finishing Options

Choose resin and finishing options to match your performance and appearance targets.

- Rigid (ABS-like) for functional testing

- Flexible (rubber-like) for grips, seals, overmould-feel

- Clear / translucent for lenses and display covers

- Colour matching (pigmented resins) for brand samples

- Paint, texture, matte/gloss clear coat for show models

- Flame Retardant for UL 94V-0 rated compliant material

Get a Fast Quote for Vacuum Casting

Upload your CAD file or share your requirements. We’ll advise on design, material selection and lead time.

Vacuum Casting FAQ

Quick answers to common questions about urethane casting, lead time, volume, and accuracy.

What is vacuum casting (urethane casting)? +

How many parts can one silicone mould produce? +

Is vacuum casting better than 3D printing? +

Can you match specific plastics (ABS, PP, rubber-like and more)? +

What files do you need for quotation? +

Vacuum Casting (Urethane Casting, Silicone Molding) Gallery: