Sheet Metal Fabrication

Precision sheet metal fabrication for prototypes and production—engineered for fit, finish, and repeatability. From laser-cut blanks and press-brake bending to welding, inserts, and finishing, we deliver custom parts and assemblies built to your specification.

- Prototype → Production

- Laser Cutting • Bending

- Welding • Inserts • Assembly

- Powder Coat • Plating • Anodize

Pic:

“Precision sheet metal fabrication—laser cutting and press brake bending in Singapore”.

Pic:

“Precision sheet metal fabrication—laser cutting and press brake bending in Singapore”.

Why Additive3D Asia

Get production-ready sheet metal parts with a team that thinks like engineers—optimising for manufacturability, quality, and delivery timelines.

Quality & Repeatability

Inspection-focused workflow to meet functional tolerances and aesthetic requirements—ideal for enclosures, brackets, panels and frames.

DFM-Driven Engineering Support

Design-for-manufacture guidance on bend allowances, hole placement, inserts, weld access, finish selection and cost optimisation.

Scalable Production

From one-off prototypes to batch production—supported by reliable supply chain, finishing partners, and hybrid manufacturing options.

Sheet Metal Capabilities

End-to-end fabrication services that turn flat sheet into precision parts and assemblies—ready for installation.

Cutting & Preparation

Laser cutting, shearing/blanking and profiling for clean edges and accurate hole patterns—optimised for bending and assembly.

Bending & Forming

Press-brake bending and forming for brackets, channels, enclosures and panels—maintaining alignment, symmetry and fit.

Joining & Assembly

Welding, PEM inserts, rivets, fasteners and sub-assemblies—delivered as ready-to-use components where required.

Finishing

Enhance corrosion resistance and appearance with finishing options selected to match performance and brand requirements.

Applications

Common sheet metal parts we support across industrial and commercial product development.

Enclosures & Housings

Electrical cabinets, control boxes, instrument housings and racks designed for fit, airflow and service access.

Brackets & Mounts

Structural brackets, mounting plates, stiffeners and supports with consistent bends and hole alignment.

Panels & Frames

Machine panels, covers, guards and welded frames built to withstand operational environments.

Materials

We help you select materials based on strength, corrosion resistance, weight and budget.

- Stainless Steel — durable, corrosion-resistant for harsh environments.

- Aluminium — lightweight, excellent strength-to-weight ratio.

- Mild / Galvanised Steel — cost-effective structural solutions.

- Brass / Copper — conductivity, decorative or specialised requirements.

If you only have a concept (no CAD), send a sketch or reference and we’ll guide you on manufacturable geometry and material choice.

Quality & Tolerances

Our workflow focuses on consistency for both functional and cosmetic parts.

We recommend providing: 2D drawings (DXF/DWG/PDF), critical dimensions, tolerance callouts, finish requirements, and intended use environment (e.g., indoor, outdoor, corrosive).

Need hybrid manufacturing? We can also integrate CNC machining and additive manufacturing for complex features, rapid iterations, and consolidated assemblies.

How It Works

A simple, engineering-led process—from file upload to delivery.

1) Share Your Files

Upload CAD/drawings and finish requirements. If you’re unsure, share a reference and we’ll assist.

2) DFM Review & Quote

We confirm manufacturability, propose optimisations and provide a clear quotation and lead time.

3) Fabricate & Deliver

We produce, inspect, finish and deliver parts—ready for installation or downstream assembly.

FAQ

Quick answers to common sheet metal fabrication questions.

What is sheet metal fabrication?

Sheet metal fabrication transforms flat sheet into functional parts using cutting, bending/forming and joining processes such as welding, inserts and fasteners—often followed by finishing.

Can you support both prototypes and production?

Yes. We support one-off prototypes, pilot batches and scalable production runs—optimised for cost, lead time and repeatability.

What finishing options are available?

Common finishes include powder coating, painting, plating and anodising (for aluminium), plus labeling/screen printing where required.

What files should I send for quotation?

Ideally 2D drawings (DXF/DWG/PDF) and/or 3D CAD, with thickness, material, quantity, critical tolerances and finish requirements.

Request a Quote for Sheet Metal Fabrication

Share your drawings or CAD files and our team will advise on manufacturability, materials, finishes and lead times.

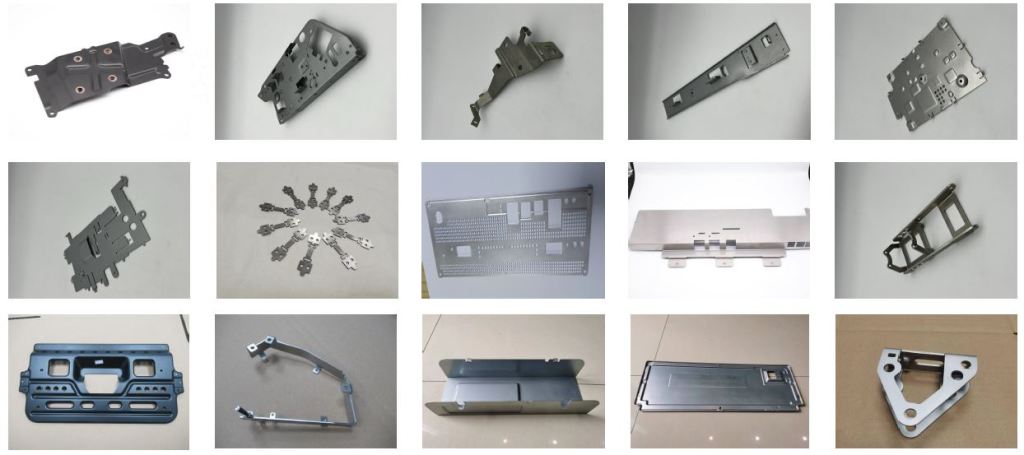

Sheet Metal Fabrication Gallery: