How to Unlock New Additive Possibilities with Chemical Vapor Smoothing in Asia

Learn how the all new post processing method Vapor Smoothing can help you attain 3D prints sealed against liquids and gases, with better tensile strength, elongation-at-break and colour.

What is inside?

AMT’s CEO Joseph Crabtree and Additive3D Asia’s Co-Founder Jason Joo share how to bring your production to the next level with Chemical Vapor Smoothing. This technology can not only seal your 3D prints against all liquids and gases, it simultaneously enhances prints in terms of elongation-at-break, tensile strength, colour, surface finishing. Expect STRONGER, WATERTIGHT & BETTER parts!

Benefits of Vapor Smoothing

Increased Mechanical Properties

Due to the removal of surface porosity, extensive testing demonstrates that vapor smoothed demonstrated no loss in Ultimate Tensile Strength (UTS) with an increase in Elongation at Break (EAB).

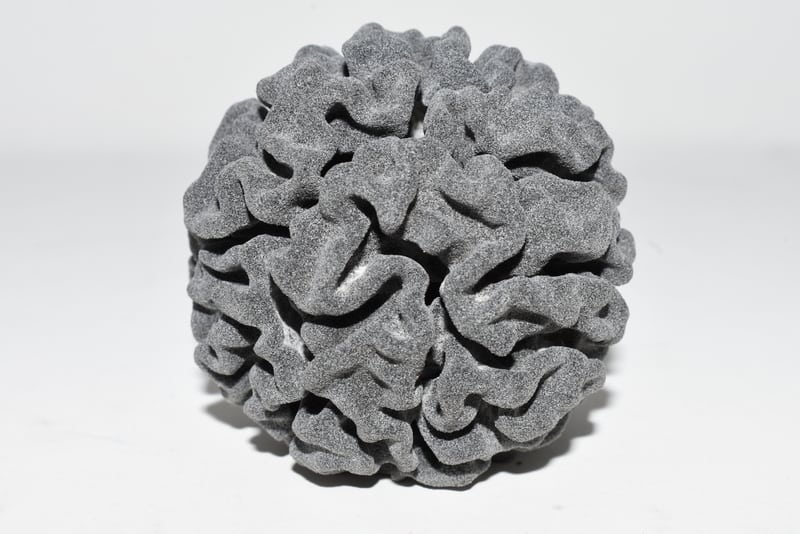

Injection Molding-Like Surface

Using a series of predefined parameters, this process achieves for the first time a surface finish that matches injection molding techniques with an RA of less than 1 micron.

Dimensional Accuracy

The process does not degrade the mechanical properties of the parts. After going through the treatment, parts exhibit no more than a 0.4%-dimensional change irrespective of the desired finish level.

Seals Against Liquid & Gas Intake

The treatment completely seals the surface, eliminating liquid or gas intake. As a result, parts become watertight and airtight.

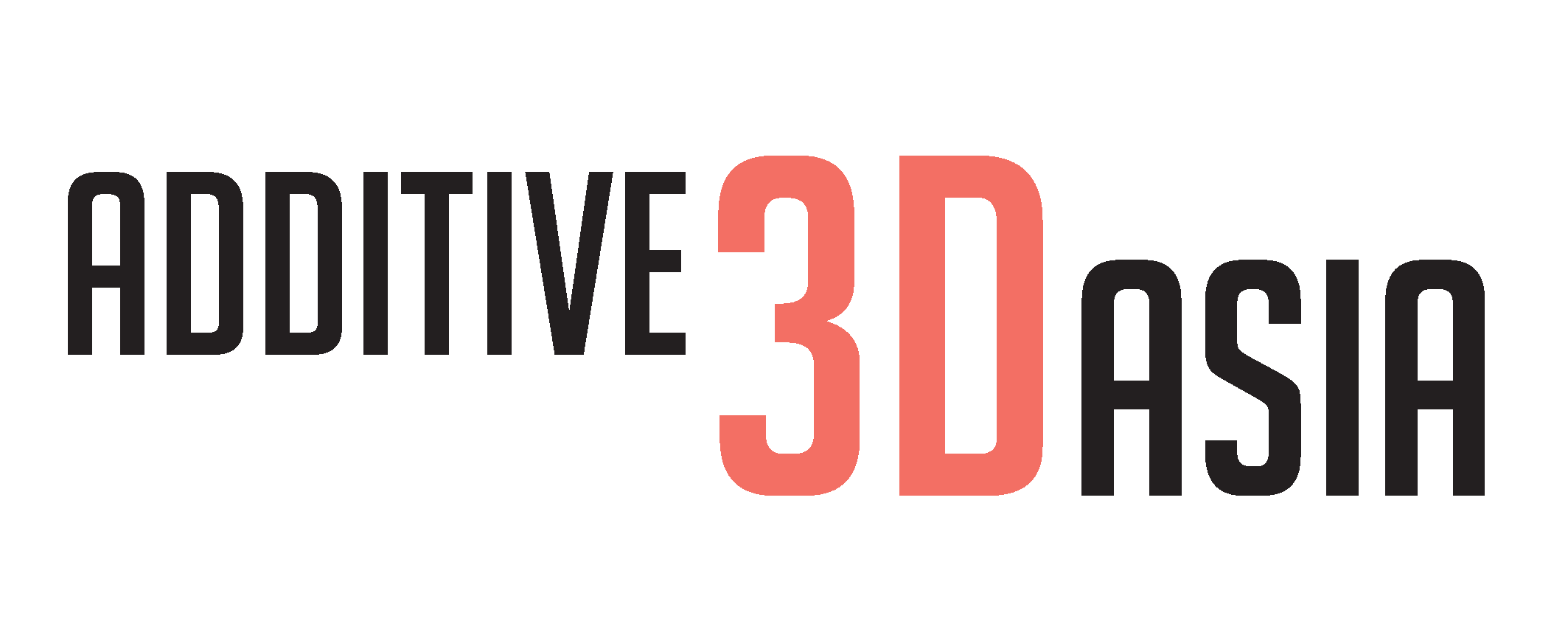

Enhances Colour

Vapor smoothing enhances the colour consistency and hue of coloured part. Additionally, parts that already have colour, such as HP MJF 580 parts, do not bleed in PostPro 3D machines.

Reduction in Bacteria Growth

Tests have shown the reduction of bacteria growth and attachment on parts that have been chemically vapor smoothed.