Bring Out the Intricacy of Parts Through Polyjet 3D Printing Services

Many of the world’s leading companies have recognised how the 3D printing revolution is here to stay. With this incredible technology serving as a game-changer for the rapid production of prototypes and end-use products, the 3D printing industry continues to grow every day. However, if your business in Singapore is considering getting on board with this evolution, it’s important to understand which 3D printing service best suits your needs.

While there are a great variety of options on the market today with various pros and cons depending on your requirements, one of the most exciting 3D printing technologies is known as PolyJet. Developed in 1999 by Objet – which later merged with Stratasys – PolyJet offers high-resolution prints in full colour and a wide variety of materials, ensuring it’s one of the go-to 3D printing services for a myriad of purposes.

What is Polyjet 3D Printing?

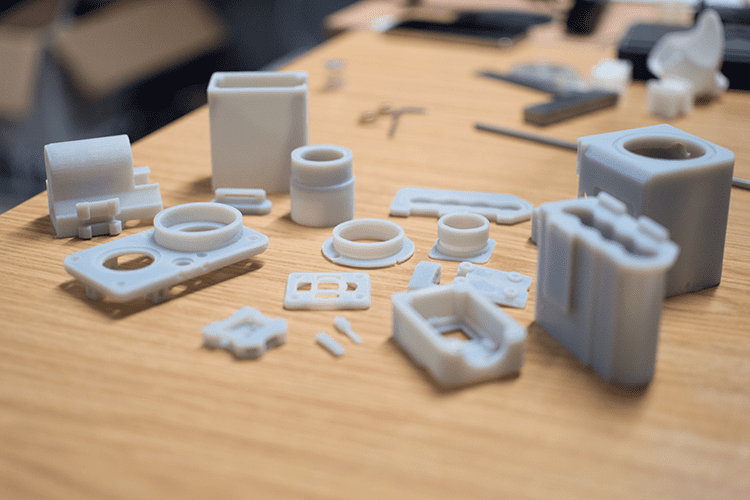

Drawing comparisons to the 3D printing method of SLA, PolyJet uses liquid photopolymers in an inkjet printer to create wonderfully detailed parts for a huge range of applications. In fact, PolyJet 3D printing can rapidly produce highly complex, multi-material parts involving different textures, colours and design requirements.

While PolyJet is highly advantageous for 3D printing end-use parts and products, it truly stands out as a great way to produce prototypes with varied properties such as strength and flexibility. As this comprehensive process quickly reveals design flaws, designers can make rapid adjustments to perfect their product and reach the production stage faster than ever before.

How does Polyjet 3D Printing work?

Using photopolymer resin materials like VeroClear and VeroWhite, these are loaded into the material container and heated. Then, using multiple print heads like an inkjet printer, these materials are sprayed onto a build tray in layers as fine as 16 microns. Once these photopolymers encounter UV light, they are instantly cured into solid layers that form the 3D object. Finally, this process is repeated layer by layer until the product is complete.

The Benefits of Polyjet 3D Printing

1. Smooth surface finish

For starters, PolyJet 3D printing is one of the top choices for products and parts featuring a smooth surface finish. Featuring an accuracy of 0.1mm, it’s possible to produce remarkably thin walls and detailed geometries.

2. Soluble support material

Additionally, PolyJet 3D printing uses soluble support materials which dissolve in a water-based solution. This distinctive feature ensures you can print detailed components and remove the supports without damaging your part.

3. Multi-material capability

Perhaps the key advantage of PolyJet is how it can be used for 3D printing multi-material parts and products. As this technology can mix various materials to create unique properties and colours, it’s possible to generate different strengths and flexibilities in a single print run.

PolyJet 3D Printing vs Other 3D Printing Technologies

With every 3D printing method having different strengths and weaknesses, PolyJet is often compared to SLA 3D printing. Although the two technologies are both frequently used to produce high-quality prototypes, there are several distinctions in the process that might make one more ideal than the other in your specific circumstances.

SLA 3D printers can only use one material at a time, while PolyJet uses multiple print heads to deposit its photopolymer material. Meanwhile, PolyJet is also one of the fastest 3D printing services, with the capacity to print parts within a five-inch cube in under two hours. Alongside PolyJet’s robust industrial parts and products, many manufacturers are using this method instead of traditional injection moulding.

Want to try Polyjet 3D Printing?

Getting started with PolyJet 3D printing services is simple. Just upload your 3D files to our system and get an instant quote from the expert team at Additive3D Asia. In fact, we can use our CAD services to take your 2D sketches and produce a top-notch 3D model that brings your idea to life. Get in touch to find out more today.