Production with Industrial Selective Laser Melting (SLM) 3D Printing Technology

Serving industries from Automotive, Aerospace (Aviation), Machinery, Medical, Moulding, Industrial Parts and more…

More than 80% of the metal 3D printing parts today are made from a Selective Laser Melting industrial 3D printer. Selective laser melting or SLM is one of many proprietary names for a metal additive manufacturing technology that uses a bed of powder with a source of heat to create metal parts.

Also known as direct metal laser sintering or DMLS, the ASTM standard term is powder bed fusion or PBF.

Applications of metal 3D printing includes: Custom Tools, End-of-Arm Tooling, Low-Volume and Specialty Parts, Surgical and Dental Implants, Jewelry and Decorative Arts, Complex Bracketry, Functional Metal Prototypes and Spare and Obsolete Parts.

Stainless steel (316L) is a good metal material for functional parts and spare parts.

Advantages:

Available Colors:

Available Post Processing:

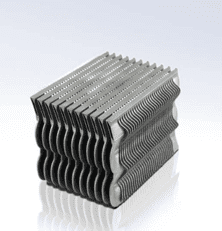

Aluminum Alloy (AlSi10Mg) is the most widely used class of non-ferrous metal structure materials in the industry. The models printed has low density but relatively high strength which is close to or beyond high-quality steel.

Advantages:

Available Colors:

Available Post Processing:

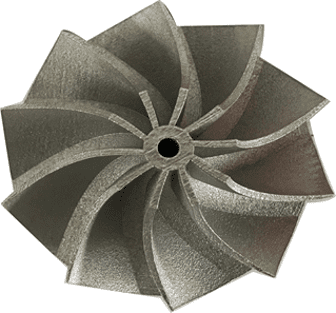

Titanium Alloys (Ti6Al4V) are alloys based on titanium with other elements added. With the characteristics of high strength, good corrosion resistance and high heat resistance, it has been widely used in various fields.

Advantages:

Available Colors:

Available Post Processing:

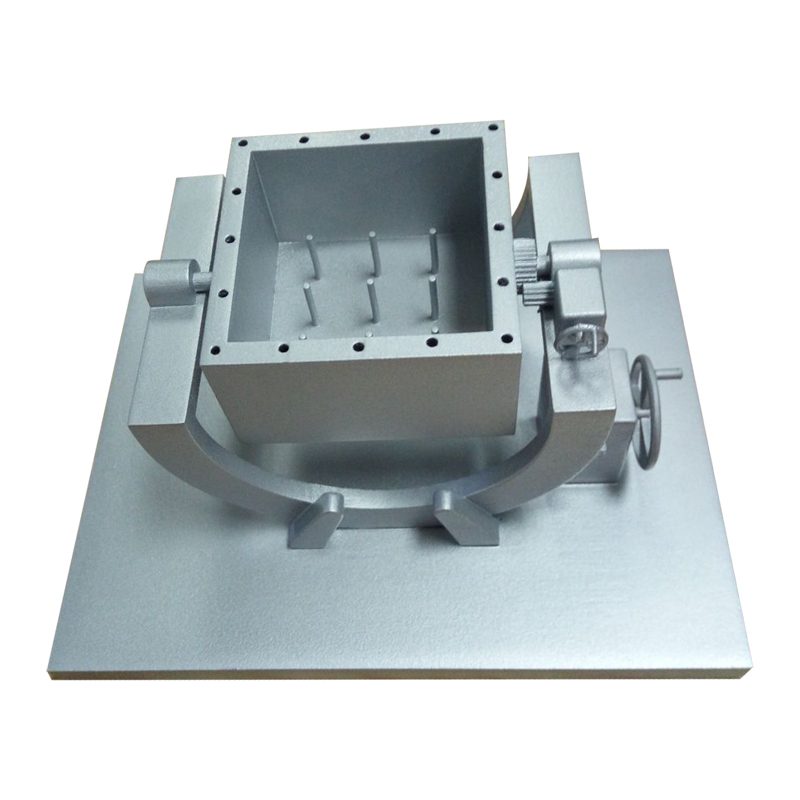

Miraging Steel (MS1 – 18Ni300) has the advantages in reducing molding cycle, improving product quality, and more uniform mold temperature field. It can print the front and rear mold cores, inserts, sliders, guide posts and hot runner water jackets of injection molds.

Advantages:

Available Colors:

Available Post Processing: