What is 3D Printing?

The Beginner's Guide To 3D Printing

How Does 3D Printing Work?

3D printing refers to the process of building a physical model from a 3D printer. All 3D printers basically work with the same idea, by adding material layer by layer until the desired object is formed. This therefore gives 3D printing its technical term – Additive Manufacturing (AM). The process operates using a different approach in comparison to traditional ways of producing parts, such as CNC Machining or Injection Moulding.

Additive Manufacturing Processes

There are many 3D printing technologies and materials offered in the market today to cater to each of your requirements and specifications.

One of the most popular AM processes in the industry is Fused Deposition Modeling (FDM). During this process, the 3D printer extrudes filament to create a 3D object layer by layer along a specifically determined path

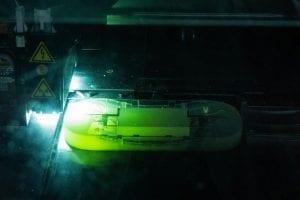

Stereolithography (SLA), despite being the oldest 3D printing technology, is also another commonly used technology. This is due to its smooth finishing, high precision and accuracy as well as fine detail. SLA is vastly different from FDM, in that it is a liquid based 3D printing technique while the latter is solid based. SLA also prints from top to bottom.

Like SLA, Polyjet is a liquid based technology that builds parts with photopolymer resins. It also utilizes the same resins as SLA. In comparison, polyjet is able to produce parts at a much faster speed.

When printing functional prototypes, many opt for Selective Laser Sintering (SLS) due to its robust properties. The durability of SLS parts are comparable to those produced via traditional manufacturing.

Unveiled only in 2016, Multi Jet Fusion (MJF) is one of the most advanced 3D printing technologies in the market today. MJF can create ultra-thin layers of 80 microns, which produces parts with high density and low porosity compared to the same PA 12 parts printed with SLS. MJF parts are also stronger and more precise.

Benefits of Additive Manufacturing

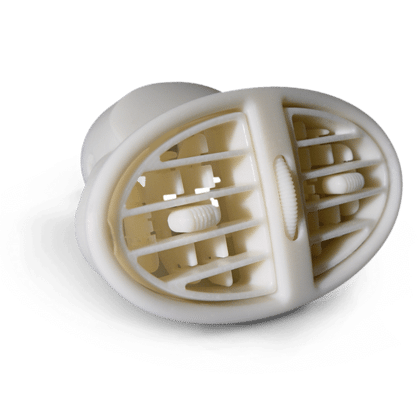

1. Freedom of Design

3D printing introduces endless geometric possibilities. When producing parts using traditional manufacturing, businesses often have to follow strict design for manufacturing (DFM) rules. DFM refers to the process of designing or engineering a product in order to facilitate the manufacturing process to reduce manufacturing costs. With the advancements of the AM industry, traditional design restrictions no longer exist, as complex designs do not come at additional costs with additive manufacturing techniques. In fact, no design is impossible as long as there is the correct support for it.

2. Mass Customization

One of the key benefits of 3D printing is its ability to customize. Of course, customization is possible with traditional manufacturing. However, this usually only happens during the last step – choosing colour and accessories of the product. Additive manufacturing takes one step further from this, by incorporating customization from the very beginning.

For example, in dentistry, 3D printing is used to produce crowns and dentures unique to each individual. In the automotive industry, Volkswaagen utilizes 3D printing to customize gear knobs for customers. In terms of consumer goods, 3D printed earbuds Normal prides themselves on the slogan “one size fits none”, meaning their earbuds are personalized for each of their customers.

3. Reducing Time & Cost

Parts produced using traditional manufacturing require moulds, which may be expensive and take up to months to prepare. If you make alterations to your design, the mould will have to be changed as well, resulting in a higher cost. However, you don’t have to worry about this with additive manufacturing. As 3D printing works on the basis of depositing material layer by layer, there is no need for costly moulds. Instead, only a 3D file and a 3D printer is required. With 3D printing, parts can be printed as quickly as a few hours!

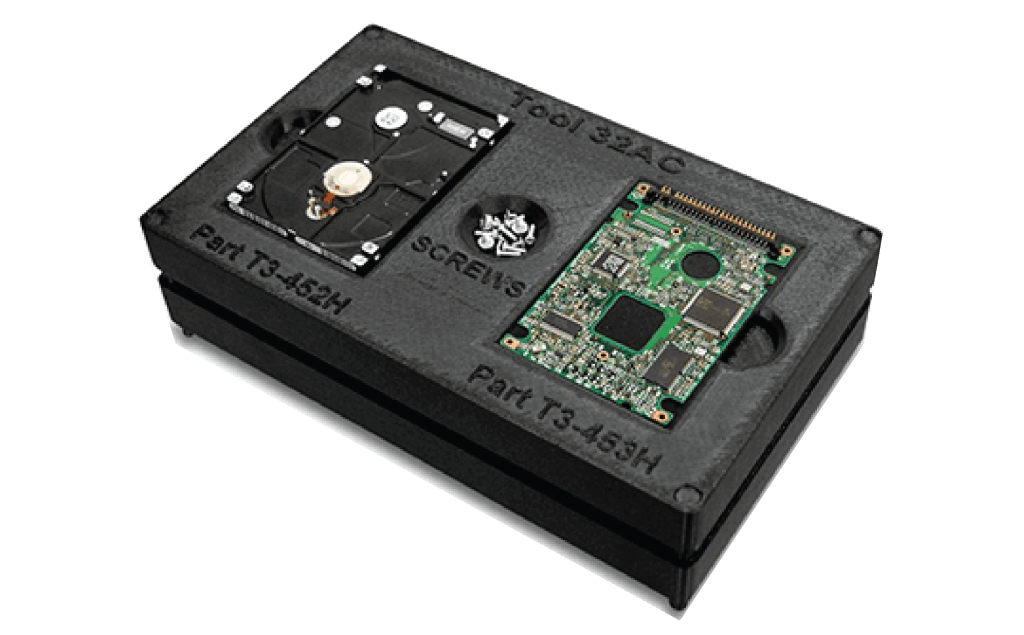

4. Industrial Materials

As an ISO 9001:2015 certified 3D printing service bureau, Additive3D Asia offers industrial materials to cater to your business requirements. This includes the ABS-ESD7 with static-dissipative properties, ideal for the semi-conductor industry. There is also the ABS-M30 which is 25 to 70 percent stronger than standard ABS, ClearVue (transparent) which is great for making prototypes with high clarity, and many more.