3D Printing VS Traditional Manufacturing:

Which Is More Suitable For Your Business?

A Business Solution To Help You Make A Financially Savvy Decision

Challenges in Fitting 3D Printing into Production Cycle

3D Printing VS Traditional Manufacturing – which is better? The production of each part will cause you to arrive at a different conclusion, due to the individuality of each and every part.

Additive Manufacturing is a vital part of the Industry 4.0 “smart manufacturing” process, claiming to radically and positively change the way businesses manufacture their products.

Businesses are always finding ways to reduce production cost. However, despite its bold claim, it is safe to say that not all businesses have utilised the advantages of 3D printing.

This is largely due to the fact that manufacturers experience difficulty in fitting 3D printing into the production cycle, especially in terms of identifying parts suitable for 3D printing.

In fact, a whopping 51% of manufacturers acknowledge that a knowledge gap in additive manufacturing is the major reason for its limited growth. This knowledge gap refers to companies not having sufficient information and in-house expertise to utilise 3D printing to reduce production cost.

Digital Part Analysis

Despite the potential to generate savings, it does not make sense financially to hire technicians to identify if 3D printing will be a suitable proposition for businesses.

This is where Digital Part Analysis comes into play. The solution is built with AI technology to quickly analyse and recommend the right technology and materials from its vast internal library. We provide you the detailed technical analysis, from a single individual CAD file to full-blown CAD assembly BOM files or an inventory list containing a combination of thousands of parts.

How Does It Work?

The Digital Parts Analyser evaluates the suitability of 3D Printing VS Traditional Manufacturing for your parts by carefully examining a few key factors.

1. Wall Thickness

Is the minimal wall of the part thicker than the limitation of a 3D printer?

2. Material Strength

When switching to Additive Manufacturing, does the object still have the same functionality as its traditionally manufactured counterpart?

3. Cost Per Part

Of course, one of the most important factors is the cost. The Digital Part Analyser determines if the 3D printed part would be cheaper than CNC.

4. Lead Time

The amount of time taken to produce the part, and if it will match your business efficiency.

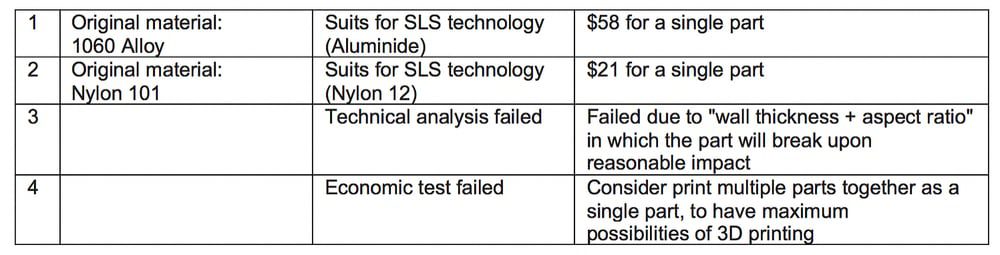

Example of a Report

The Digital Part Analyser recommends suitable technologies for the part. This comes with the required cost to print one part using the technology.

Although not all parts are suitable for Additive Manufacturing, this report helps Production Engineers to have a clearer overview. Business are able to evaluate the opportunity for Additive Manufacturing without having to actually send parts into production. This prevents a failure where parts are produced with an unsatisfactory end result. Thus, time and cost is saved in the process.