HP MJF 3D Printing: Accelerating Build Time for Parts

While Selective Laser Sintering (SLS) printing was invented in the 1980s, Multi Jet Fusion (MJF) is a much newer technology introduced by Hewlett-Packard (HP) in 2016. Despite its relative infancy, MJF has quickly become a great addition to 3D manufacturing in Singapore and globally, specifically when creating functional final parts for end-use, low-volume production, manufacturing aids, rapid prototyping, or as a bridge process to injection moulding. MJF is a powerful 3D printing technology that produces highly accurate and durable parts at fast speeds, especially compared to other powder bed fusion technologies. If your business is considering MJF to produce 3D printed parts, check out these answers to some of the commonly asked questions to gain a detailed picture of this process.

1. What is MJF 3D printing?

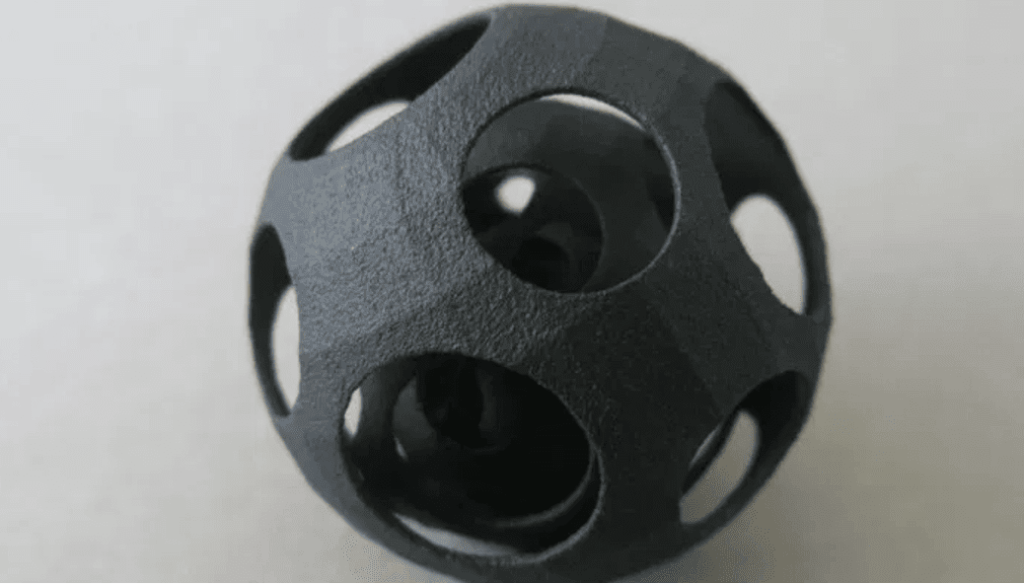

Using inkjet technology, also known as binder jetting, Multi Jet Fusion applies both fusing and detailing agents to a layer of nylon powder. The fusing agent is printed along the edge of the part before a heated infrared source blankets the object. This causes the fusing agent to melt with any underlying layers, gradually forming the product layer by layer, while the areas with detailing agent remain as powder.

Eventually, the unheated powder gets removed and the product takes shape. Throughout the printing process, the lower layers provide the object with essential stability. More importantly, this means you won’t have to worry about using support structures, which may add extra costs and reduce surface quality in other methods.

2. What are some key benefits of MJF 3D printing?

- Economical cost per part: Multi Jet Fusion has some of the lowest economical per part costs of any 3D printing technology, though the barrier to entry to own a HP MJF printer it is not as accessible as an FDM printer.

- Fast printing process: MJF is 10 X faster than Selective Laser Sintering as it heats a whole layer at once, rather than tracing each area.

- Watertight (Fluid-Tightness): Parts produce with MJF as the standard build parameters are optimized for the best density

- More environmentally friendly: With SLS, you usually get around 50% material good enough to reuse after a print. MJF is far better than this, and is aided by the processing station which sucks excess material back in to the printer to be reused, and can also clean prints. Less wasted plastic powder means less environmental damage.

- Ability to print colour parts: Whereas other technologies like FDM, SLA and SLS are limited by choices of single colour, HP offer an option from other range of printers that can print in full multi colour. This eliminates the need to paint or dye the print after printing.

- Very smooth surface areas: the MJF printing process creates crisper edges than technologies such as (SLS), so often MJF parts will appear smoother. This is because MJF delivers more balanced mechanical properties across the X, Y, and Z axes compared to SLS.

3. What makes MJF printing different from SLS printing?

While MJF and SLS 3D printing are both great for industrial applications, there are a few key differences. Although these powder-based methods print layer by layer, MJF printers have detachable build platforms that significantly reduce cooling times compared to SLS alternatives.

The heat source also differs between MJF and SLS. While the latter uses a laser to scan and sinter each cross-section, MJF coats the powder in a fusing agent to absorb infrared light. Then this passes over the build platform and binds the appropriate areas. Thanks to its faster printing speeds, MJF can offer shorter product development lead times.

4. What are some industries that are using MJF 3D printing?

With MJF offering fast, durable and precise 3D printing, it’s quickly become one of the go-to technologies for numerous industries, ranging from the aerospace, automotive, industrial, electronics, medical sectors to consumer goods. These complex and customised products include everything from eyewear, medical devices, parts for a complete products assembly, prosthetics, living hinges to insoles.

In fact, many of the world’s leading companies have adopted MJF printing into their product development cycle. For example, in response to the COVID-19 pandemic globally, the need for certified safe NASAL Swabs of over 0.7 million was produce by HP and its network of manufacturing partners as it was faster compared to traditional manufacturing. And Oakley uses MJF printing to streamline its sunglasses development, while Jaguar Land Rover produces interior fixtures for its luxury vehicles and there are many more examples from other industries leveraging on MJF technology. As this technology evolves further, even more exciting applications are bound to emerge in the near future.

Contact Our Expert Team

Want to give MJF 3D printing a try? Here at Additive3D Asia, we help clients from across the industrial and manufacturing industries get started with 3D printing technology. As one of Singapore’s leading specialists in additive manufacturing, let us evaluate your product requirements and advise on the right solution to 3D print your parts. Contact our friendly team to find out more.