What are the Post Processing methods in 3D Printing?

3D printed parts often require some sort of post processing. The term “post processing” encompasses many methods and technologies. Therefore, many beginners to 3D printing often have the same question – what exactly is post processing in 3D printing? Post processing in 3D printing is an umbrella term, consisting but not limited to spray painting, metallization, polishing to clear, and its newest technology – vapor smoothing.

The Different Post Processing Methods in 3D Printing in Singapore

1. Spray Painting

Spray painting is the most straightforward technique for post processing your 3D prints. With the right skills, spray painting can create a professional and even finish. We advise to keep a healthy distance of around 10 inches between the nozzle of your spray can and the part. For finishing touches, spray from a further distance. The important thing to remember when spray painting is to go light-handed, as you can always add more layers if needed, but the reverse is hardly possible.

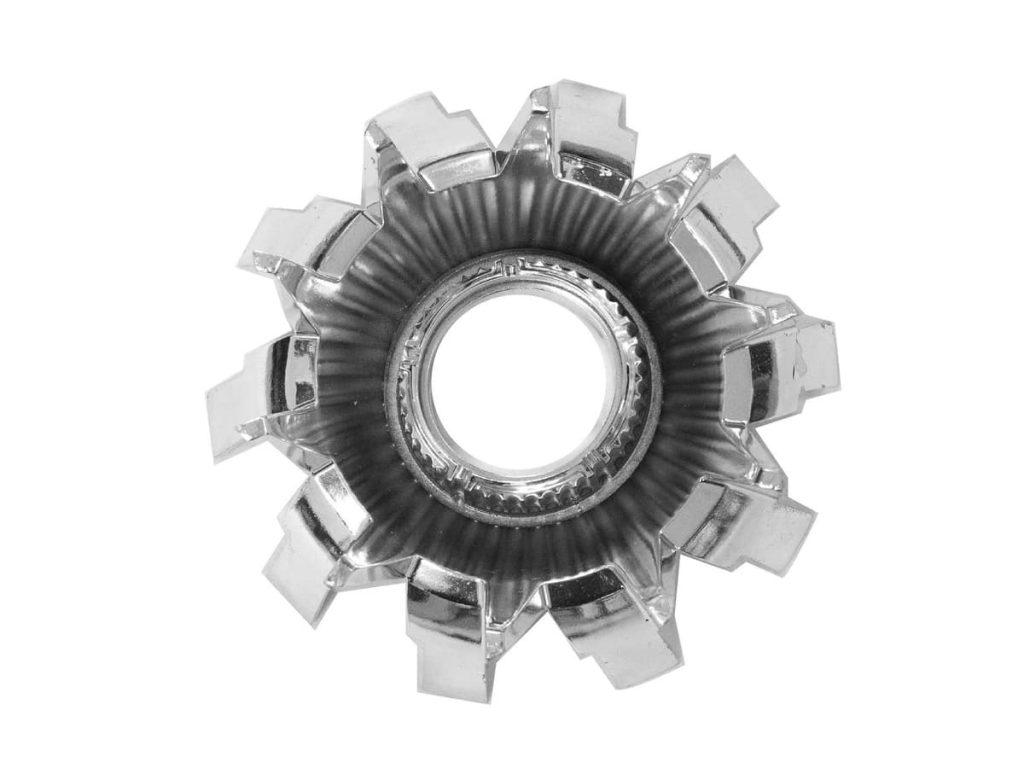

2. Metallization

Metal 3D printing has been garnering increased attention globally. However, the technology comes with a hefty price tag, with a typical Direct Metal Laser Sintering (DMLS) part costing approximately $5,000 to $10,000.

With such a heavy upfront cost, instead of printing the whole part in metal, many 3D printing adopters opt for metallization – a process that provides you with a metal-like surface finish. Coating 3D printed parts with metal also provides the part with greater strength and protection against heat and corrosion when it subsequently receives an electrolytic deposit.

As machinery is required to perform this technique, we suggest you to locate a service provider such as Additive3D Asia that offers metallization.

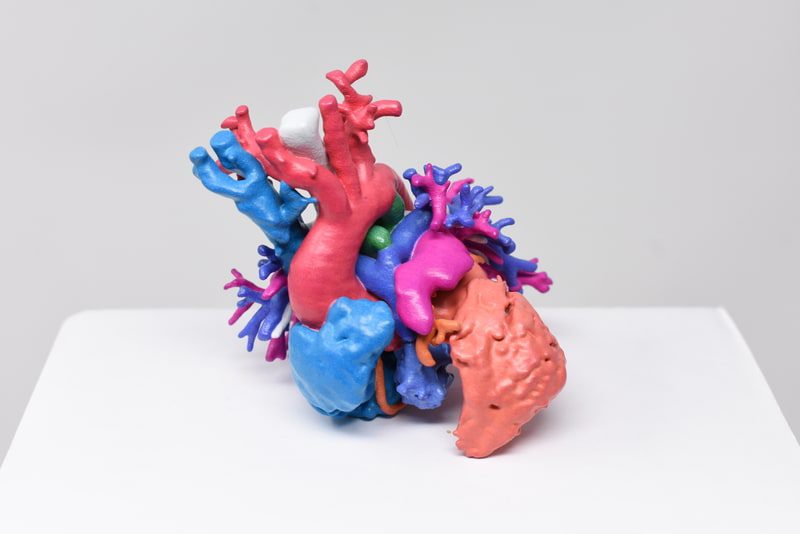

3. Polishing to Optic Clear

Polishing to optic clear is another popular choice for post processing in 3D printing. With some polishing, you will be able to achieve clear looking plastic prints easily. This is especially useful for prototypes or marketing purposes!

Clear parts can be manually sanded and polished to obtain clarity not unlike a magnifying glass. However, one point to note is that complex designs are difficult to polish without expert knowledge.

4. Vapor Smoothing

Vapor smoothing is the newest method in post processing. The technique smoothens parts to achieve an injection molding-like surface without degradation of its mechanical properties. Simultaneously, the part’s elongation-at-break (EAB) will be strengthened and it also seals against liquids and gases. This process is tested and compatible with up to 95% of all 3D printing materials. For more information about vapor smoothing, get in touch with Additive3D Asia, the first to offer this technology in all of Southeast Asia.